NERC 4-year PhD studentship: From whole algae to crude oil – an interdisciplinary approach to tackle mine waste.

Dr Mark van der Giezen [1], Dr Chris Bryan [2], Dr Mike Allen [3], Dr Clive Butler [1], Dr Christopher Chuck [4].

[1] Biosciences, University of Exeter, [2] Environment and Sustainability Institute & Camborne School of Mines, [3] Plymouth Marine Laboratory, [4] Chemical Engineering, University of Bath.

A 4-year NERC-funded PhD position, to start in September 2015, is available at the University of Exeter. This multidisciplinary PhD will combine environmental biology, microbiology, bioenergy, hydrometallurgy and phycology, and will provide the student with excellent training for a research career.

Water pollution is a major global problem and accounts for the deaths of more than 14,000 people per day. It is speculated that lack of clean water will rise to catastrophic proportions by 2025. It is estimated that then, 1.8 billion people will be living in areas with absolute water scarcity and two thirds of the world could be facing drinking water shortages.

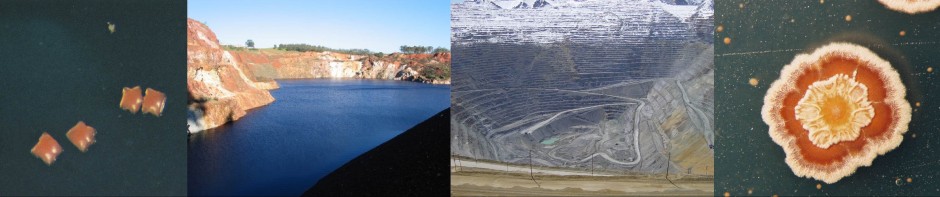

The increasing world population not only puts demands on the presence of clean water but also increases reliance on the Earth’s resources. Mining has well-publicised deleterious environmental consequences and contributes greatly to destruction of landscapes and the pollution of water. This is mainly through the generation and uncontrolled release of acid mine drainage (AMD), a highly polluted water runoff from operating or abandoned mine sites. It is caused by the biological weathering of sulfide minerals exposed during mining operations. AMD is highly acidic (pH <3.0) and transpo rts heavy metals such as iron and copper and metalloids such as arsenic from the mine into the wider environment and watercourses. It is a significant environmental problem often requiring expensive and on-going treatment long after a mine has closed. Up to 1,000 km of rivers and waterways are thought to be affected by AMD in the UK alone.

rts heavy metals such as iron and copper and metalloids such as arsenic from the mine into the wider environment and watercourses. It is a significant environmental problem often requiring expensive and on-going treatment long after a mine has closed. Up to 1,000 km of rivers and waterways are thought to be affected by AMD in the UK alone.

Thus far, algae have been trialled to remediate AMD but these systems are not competitive with chemical treatment (rate-wise) or compost wetlands (cost-wise). Additionally, challenges in algal fuel production include low growth rates, high costs of drying and lipid extraction.

However, thermochemical conversion of whole microalgae into biocrudes, which can be further upgraded into chemicals and fuels, offers a highly credible route to cost-effective fuel production. Here, oil is formed from the entire biomass, allowing use of non-lipid producing algae more suited to bioremediation. Additionally, a secondary concentrated waste stream containing heavy metals is also produced, suitable for reprocessing and additional valorisation.

This project is part of the multi-disciplinary AVaRICE project (www.avarice.org.uk) and would suit applicants from a variety of backgrounds.

For further information on the project and the position, please use the contact either Dr. Mark van der Giezen (www.vandergiezen.org/) or Dr. Chris Bryan (www.exeter.ac.uk/esi/people/bryan/). Interested candidates with a good first class honours degree, or equivalent, are strongly advised to contact the supervisors prior to the deadline which is the 15th of January 2015 (further details on how to apply will become available shortly).